Features

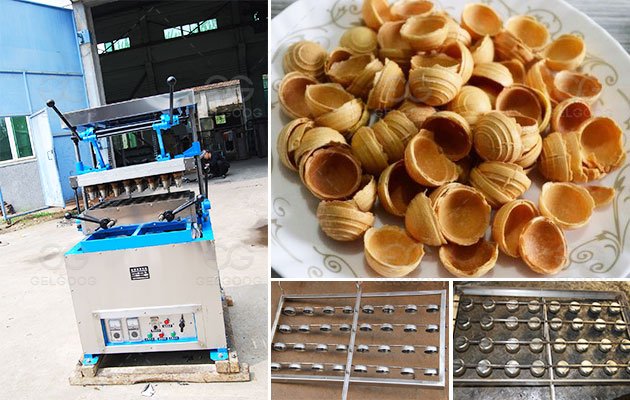

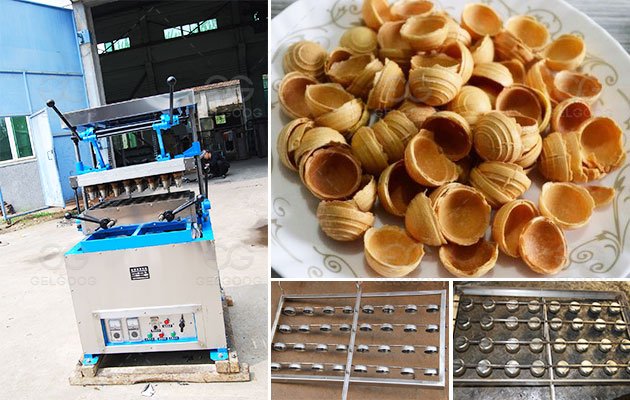

Choco shell making machine is an equipment that specializes in making choco shells, wafer shells. It is not only the price is affordable, but also has a medium output, which is very suitable for small and medium-sized commercial businesses.

Of course, in order to be able to meet the needs of more customers, our company also produces other equipment with a minimum production capacity of 200 pcs/h and a maximum of 6000 pcs/h. In addition, the wafer shell making machine can be customized.

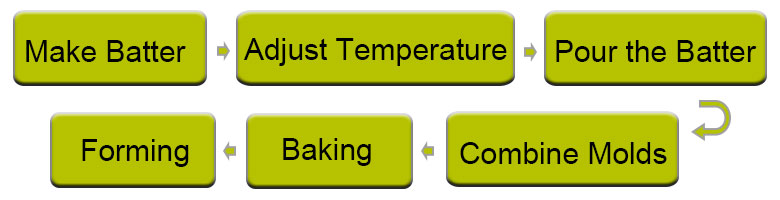

Working Principle:

How to Operate the Machine?

➱ Prepare the batter, mix well with water, flour, a small amount of sugar and other ingredients.

Of course, in order to be able to meet the needs of more customers, our company also produces other equipment with a minimum production capacity of 200 pcs/h and a maximum of 6000 pcs/h. In addition, the wafer shell making machine can be customized.

Working Principle:

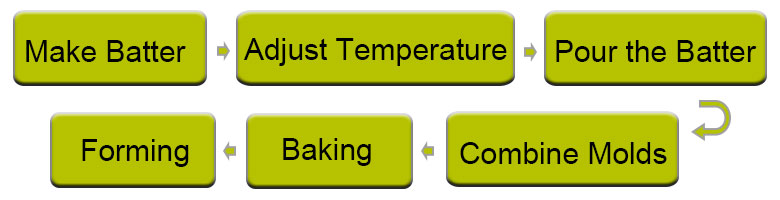

Using flour as the main raw material, add water, butter and other ingredients, stir and mix evenly, then the batter is poured into the lower mold, the upper mold and the lower mold are combined, and the batter is extruded and baked for 1 to 2 minutes to form a beautiful and edible shape choco shell.

Performance of Commercial Wafer Shell Making Machine

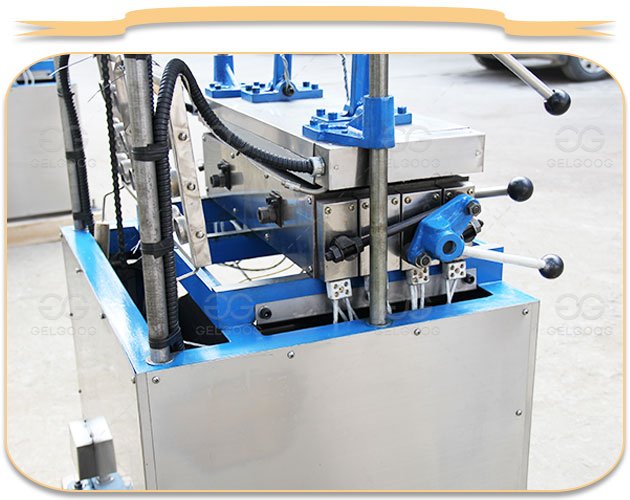

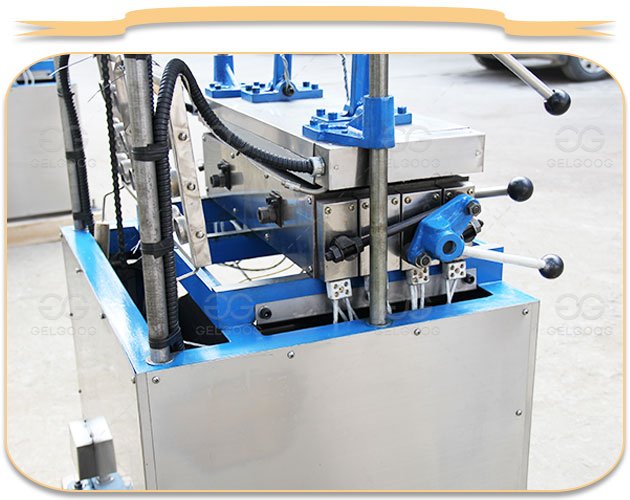

▸ This machine is professionally designed, it is simple and generous, and the whole machine structure is safe and reasonable.

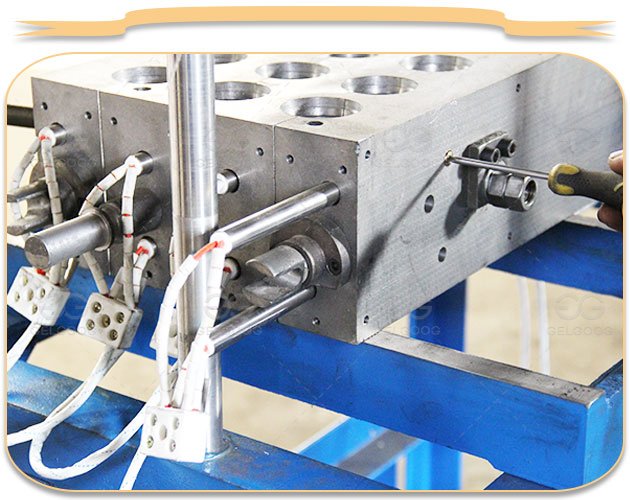

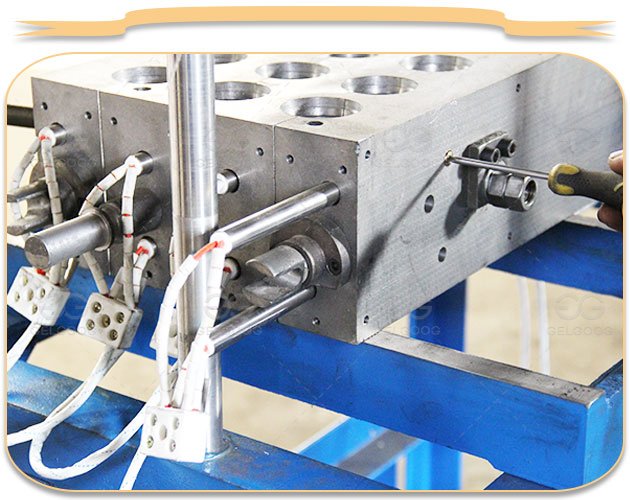

▸ The upper and lower molds are made of cast aluminum, which heats up quickly, and the finished product will not stick to the mold.

▸ The machine is equipped with a thermostat and a timer. After the batter is heated, there is a reminder device.

▸ Stainless steel structure, high-efficiency heating wire, non-stick surface treatment, conical forming mold.

▸ The chocolate choco shell machine is simple to operate, safe and in line with national health and safety standards.

The following is an choco shell making machine processing process, please watch:

The following is an choco shell making machine processing process, please watch:

Why choose our company's Choco Shell Making Machine? What is the specific reason?

◌ The same type of molds can be exchanged, which means that one machine can be exchanged with multiple molds.

◌ The wafer shell machine can produce beautiful-looking shells, which is an ideal container for chocolate balls.

◌ Produce cones of different shapes and provide three specifications: large (80-100), middle (60-80) and small (40-60) according to capacity (ml).

◌ Design and manufacture different types of cones according to the size, color and shape provided by the customer.

How to Operate the Machine?

➱ Prepare the batter, mix well with water, flour, a small amount of sugar and other ingredients.

➱ Use the temperature control knob to increase the temperature and wait for the temperature to rise.

➱ Pour the prepared batter into the lower mold of choco shell making machine, pull the upper mold, and close them.

➱ After baking for a minute or two, it becomes a cone shape, and the upper mold can be pulled up at this time.

➱ The upper mold is upward, the lower mold is opened, and the product will come out from the lower outlet.

Different models of equipment have different prices. If you are interested in our equipment, please leave us a message, and we will arrange professional personnel to contact you.

Different models of equipment have different prices. If you are interested in our equipment, please leave us a message, and we will arrange professional personnel to contact you.

Technical Data

| Model | GGDW-32C |

| Capacity(PCS/H) | 800-1000 |

| Quantity of Moulds | 32PCS |

| Baking time | 1-2 Minutes |

| Operation | Semi automatic |

| Power | 15KW |

| Voltage | 380V/220V |

| Machine size(MM) | 880*880*1380 |

| Packing size(MM) | 900*1000*1540 |

| Net Weight | 450KG |

| Gross Weight | 510KG |

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP