Features

The automatic mini cone production line is an professional equipment used to make high-quality mini cones. It also can produce high-yield sugar cones, chocolate mini cones, waffle cones, etc. according to the needs of users.

Engineers can design ice cream cone processing solutions of different scales to meet the needs of different users. And the special ice cream biscuit cone style also supports customization.

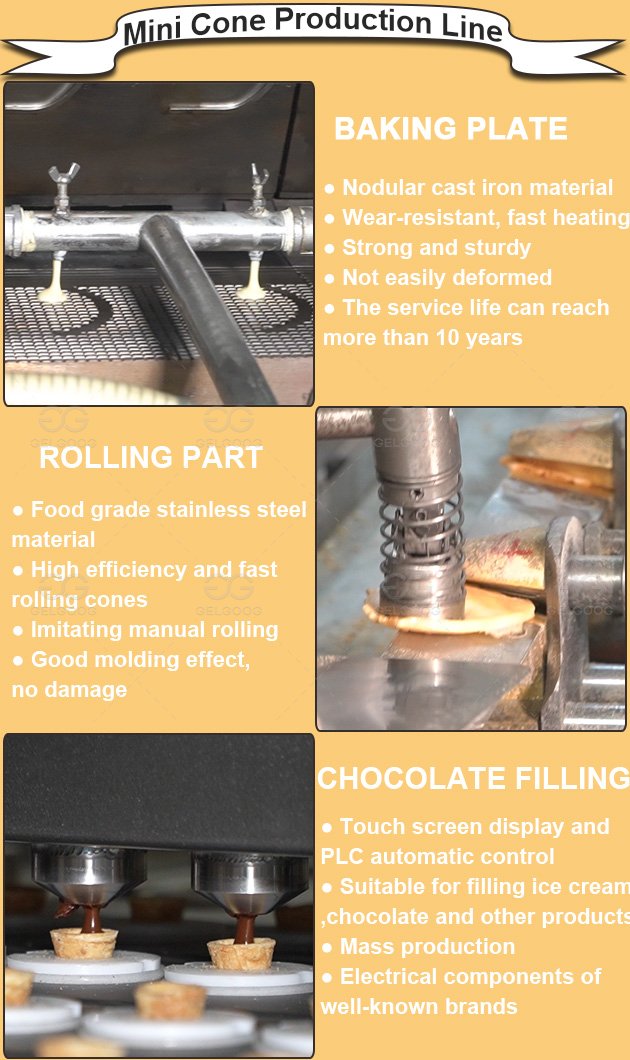

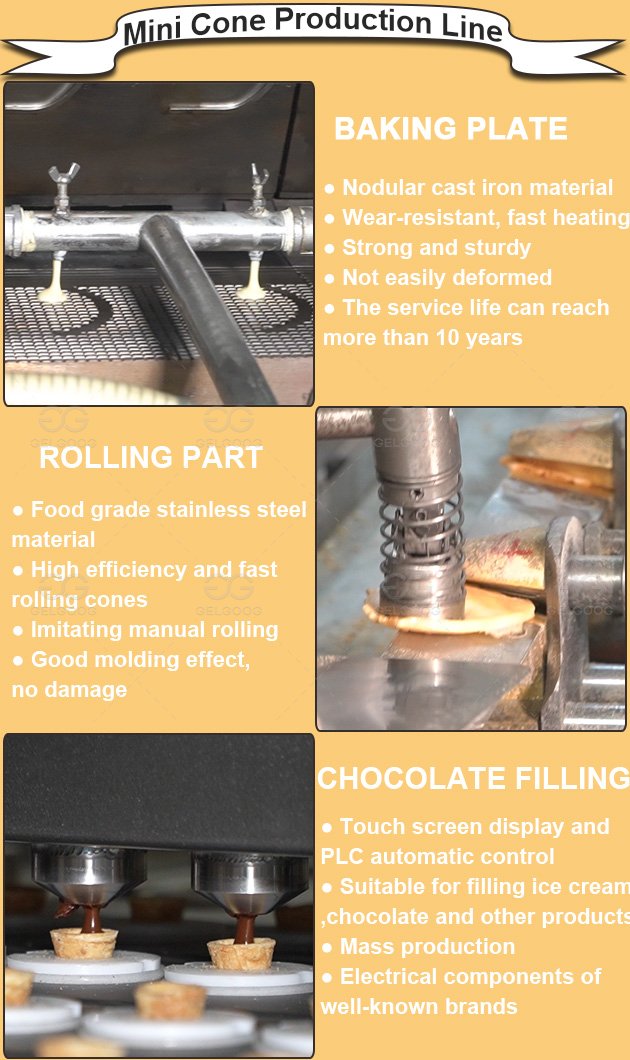

Features of Automatic Small Cone Making Machine

Engineers can design ice cream cone processing solutions of different scales to meet the needs of different users. And the special ice cream biscuit cone style also supports customization.

Working Principle of Mini Ice Cream Cone Production Line

Feed the mixed batter into the baking pan through the feed pump, close the lid, adjust the temperature, and enter the baking tunnel. After baking, the mini cone sheets are transported to the rolling mold, and finally, the finished product falls from the discharge hole.

Working Video of Bites Waffle Cone Machine

Working Video of Bites Waffle Cone Machine

Advantages of Automatic Mini Cone Production Line:

1. Fully automated production: PLC control of the whole machine, multi-language touch screen display, intuitive and simple operation, this product integrates grouting, baking, rolling, demoulding, and conveying, saving a lot of labor costs.

2. Efficient and high-yield: The general production capacity ranges from 3000 to 8000 per hour, if there are special sizes, it can be customized according to requirements.

3. Private order: This small chocolate cone line can produce ice cream cones and egg rolls of various sizes and shapes according to demand.

4. Quality assurance: The automatic mini cone machine is made of high-quality steel, and the structure is firm and durable, which ensures the stable operation of the equipment.

5. Perfect structure design: the baking part adopts the upper and lower mold design structure and is driven independently. Flexible action, good molding effect, convenient inspection, repair and maintenance.

Features of Automatic Small Cone Making Machine

1. The whole set of equipment is mainly composed of ice cream cone baking machine, mixing machine, automatic paper sleeve machine, cooling conveyor, counting machine, chocolate filling machine, chocolate heating and holding tank, freezing tunnel, packaging machine and so on.

2. The chocolate cone production line can make different products within round biscuit, sugar rolled cone, egg roll with changing the different forming devices.

3. The food-contact part of the chocolate waffle cone production line is made of high-quality stainless steel materials, and the electrical components are made of well-known brands, which are both rust-proof and corrosion-resistant, as well as sturdy and durable.

4. The size of the finished mini chocolate-filled ice cream cones is within 145mm long can be customized according customer's requirements, such as angle, width, depth, figure and thickness.

5. With various models and affordable prices, users can choose the suitable mini chocolate waffle cone machine according to their needs and budget.

5. With various models and affordable prices, users can choose the suitable mini chocolate waffle cone machine according to their needs and budget.

Technical Data

| Model | GGDCL-37 | GGDCL-45 | GGDCL-55 | GGDCL-65 | GGDCL-75 | ||

| Capacity | 3000-3500pcs/h | 3500-4000pcs/h | 4500-5000pcs/h | 5500-6250pcs/h | 7000-7500pcs/h | ||

| Power | 2.2KW, 380V 50Hz 3phase | 3KW, 380V 50Hz 3phase | |||||

| Gas consumption | 140cube/24hours | 160cube/24hours | 200cube/24hours | 240cube/24hours | 280cube/24hours | ||

| Dimension | 6.5*1.8*1.75m | 8*1.85*1.8m | 9*1.9*1.85m | 10*1.9*1.85m | 11*1.9*1.85m | ||

| Total weight | 4200kg | 4700kg | 5100kg | 6000kg | 7100kg | ||

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP