Features

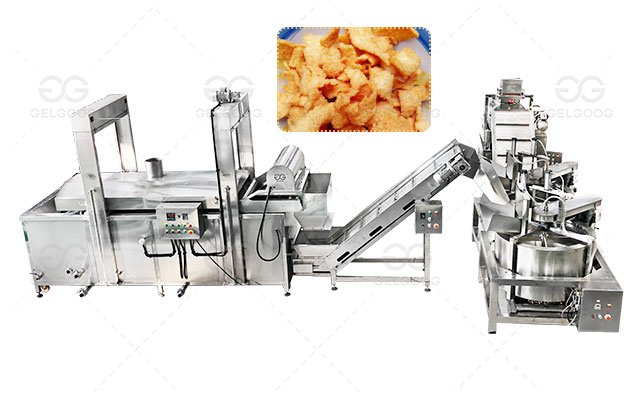

This bean chips frying machine can be used to fry bean chips, corn chips, akara chips, gyoza and other types of products. The whole machine can work continuously and has high efficiency. It can produce 300 kilograms of fried products per hour.

In order to meet the different needs of users, our company has produced different types of frying equipment. Different models have different output and different prices. Users can choose a suitable model according to their specific needs.

In order to meet the different needs of users, our company has produced different types of frying equipment. Different models have different output and different prices. Users can choose a suitable model according to their specific needs.

The Scope of Application of Akara Chips Machine:

It can deep-fry various fried products, mainly pasta and meat. Mainly chicharron, pork rinds, bacon, chicken nuggets, cutlet, fish skin, chicken skin, chicken fingers, croquette; also corn chips, tostada shells, flour chips, tortilla chips, gyoza, namkeen, kibbeh, nigeria chin chin, kuli kuli, donut, lokma, etc.

Working Video of Continuous Bean Chips Frying Machine

Working Video of Continuous Bean Chips Frying Machine

Features of Bean Chips Frying Equipment

➊Reasonable structure, adopting double mesh belt stepless variable speed adjustment, which not only guarantees the frying time of different fried products, but also ensures the smooth heating and transportation of the fried food at 2~3cm below the oil layer; adopts gantry and lifting mechanism, cover The lid is convenient to lift and fry, which is convenient for frying and processing food.

➊Reasonable structure, adopting double mesh belt stepless variable speed adjustment, which not only guarantees the frying time of different fried products, but also ensures the smooth heating and transportation of the fried food at 2~3cm below the oil layer; adopts gantry and lifting mechanism, cover The lid is convenient to lift and fry, which is convenient for frying and processing food.

➋Salad oil, peanut oil, rapeseed oil and palm oil can be used according to the needs of different frying processes for croquettes, rice cakes, potato cakes, various mixed cakes, French fries, potato chips, fish balls and meat balls, etc.

➌ The bean chips frying machine adopts the device of external filtration circulating oil circuit, so that the oil is heated by the heater in the evenly circulating flow in the main oil tank, so that the temperature of the oil rises uniformly and steadily. In addition, when the circulating oil passes through the double-layer (thick and fine) filter screen of the auxiliary oil tank, the large and small particles in the oil are removed to ensure the cleanliness of the oil, so that the fried materials are kept clean at all times.

➍ It is controlled by an electronic control instrument. When the oil temperature is higher than the set temperature, the heating device stops heating. When the oil temperature is lower than the set temperature, the heating device starts to heat to ensure the frying temperature of the product and improve the product quality.

Advantages of Akara Chips Frying Machine:

1. The main material of the continuous fryer equipment produced by our company is made of national standard SUS304 stainless steel.

2. The heat preservation design of the whole machine, high heat utilization rate, and the stainless steel outer decorative board make the whole machine beautiful and generous.

3. SUS304 stainless steel electric heating tube built-in heating, high heat utilization rate. The oil tank has a compact structure and a large oil capacity.

4. The scientific double deslagging design ensures the product quality while prolonging the life cycle of the edible oil, reducing the production cost for the enterprise.

5. Column-type lifting can realize separate or integrated lifting of the hood and mesh belt support, which is convenient for workers to clean and maintain equipment.

Technical Data

| Model | Heating type | Power | Size(MM) |

Weight (KG) |

Capacity (KG) |

Key size (MM) |

Oil discharge (L) |

gas consumption |

burner |

| GGZLD3500 | Electricity |

delivery:1.5KW Promotion: 0.75KW Heating:100KW |

3700*1400*2300 | 800 | 200 |

Mesh belt width 800 |

800L | ||

| GGZLQ3500 | Gas |

Delivery:1.5KW Promotion: 0.75KW |

3700*1700*2300 | 1200 | 200 |

Mesh belt width 800 |

1200L | 23cube | 20W Big card |

| GGZLD4000 | Electricity |

Delivery:1.5KW Promotion:0.75KW Heating:110KW |

4200*1400*2300 | 1000 | 300 |

Mesh belt width 800 |

950L | ||

| GGZLQ4000 | Gas |

delivery:1.5KW Promotion: 0.75KW |

4200*1700*2300 | 1400 | 300 |

Mesh belt width 800 |

1420L | 23cube | 20WBig card |

| GGZLD5000 | Electricity |

delivery:1.5KW Promotion: 1.5KW Heating:120KW |

5200*1400*2300 | 1200 | 500 |

Mesh belt width 800 |

1230L | ||

| GGZLQ5000 | Gas |

delivery:1.5KW Promotion: 1.5KW |

5200*1700*2300 | 1600 | 500 |

Mesh belt width 800 |

1850L | 34cube | 30WBig card |

| GGZLD6000 | Electricity |

delivery:1.5KW Promotion: 1.5KW Heating:180KW |

6200*1400*2300 | 1400 | 800 |

Mesh belt width 800 |

1520L | ||

| GGZLQ6000 | Gas |

delivery:2.2KW Promotion:1.5KW |

6200*1700*2300 | 1800 | 800 |

Mesh belt width 800 |

2280L | 45cube | 40WBig card |

| GGZLD7000 | Electricity |

delivery:2.2KW Promotion: 1.5KW Heating:210KW |

7200*1400*2300 | 1600 | 900 |

Mesh belt width 800 |

1810L | ||

| GGZLQ7000 | Gas |

delivery:2.2KW Promotion: 1.5KW |

7200*1700*2300 | 2200 | 900 |

Mesh belt width 800 |

2700L | 45cube | Two 20WBig card |

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP