Features

The commercial nigeria egg roll frying machine is a smoke-free, multi-functional, energy-saving and environmentally friendly frying equipment. It can be used for frying different materials with a wide range of types and wide applications.

All kinds of materials can be fried:

The equipment adopts the internationally advanced continuous frying technology, which changes the structure of traditional frying equipment and fundamentally solves the drawbacks of traditional frying machines.

The outstanding performance of its superiority is:

The outstanding performance of its superiority is:

①The average concentration of oil fume emitted by the ordinary type is 6.16g/m3, and this fryer is 1.96g/m3, which is 1/3 of the ordinary fryer, which is more environmentally friendly and healthy.

②The process can effectively control the oil content of the food. The fried food is not only good in color, aroma and taste, but also clean and beautiful, which improves the quality of the product and extends the shelf life.

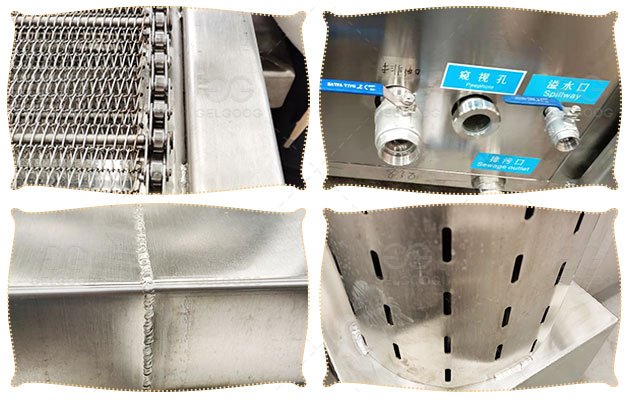

③Using the oil-water mixing process, the residue is automatically filtered to keep the oil surface clean. Use the cylinder to lift, more stable and safer.

④The machine is automatically operated, which can realize the functions of automatic feeding, automatic discharging, automatic filtering, and automatic lifting.

⑤The oil-water mixing process adopts the heating method from the middle of the oil layer to control the temperature of the upper and lower oil layers, effectively alleviating the oxidation degree of the fried oil, inhibiting the increase in acid value, and

thus prolonging the life of the fried oil. After the acid value of the oil is measured, the peroxide value and the inspection value are far less than the national standard, which greatly extends the life of the frying oil, reduces waste, and saves more than 30% of the frying oil compared with the traditional fryer.

All kinds of materials can be fried:

Pasta: chin chin, puffs, twists, samosas, bread slices, buns, corn flakes, tofu, puffed food, etc.

Nuts: peanuts, broad beans, chickpeas, green beans, cashews, melon seeds, etc.

Fruits and vegetables: French fries, potato chips, banana chips, cassava chips, yams, sweet potato chips, plantain chips, etc.

Meat: pork skin, fish skin, chicken skin, squid rings, meatballs, chicken nuggets, meatloaf, chicken wings, etc.

Nigerian Egg Roll Video:

Nigerian Egg Roll Video:

Features of Nigeria Egg Roll Frying Machine

1. The oil temperature is automatically controlled throughout the whole process, and the temperature can be set at will from 0 to 300 degrees, which is suitable for frying foods with various technological requirements.

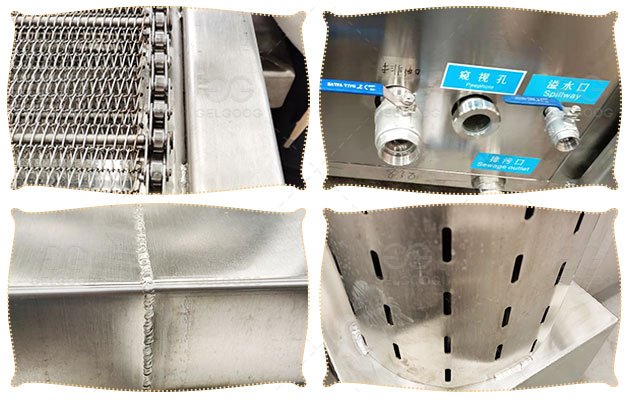

2. The water filling valve is located at the bottom oil layer. Water can be added at any time and will not affect the frying work. It is also equipped with a check valve, which solves the problem of backflowing the oil into the water pipe when the water is stopped during the water filling process. problem.

3. The food produced by this fryer process has good smoothness, bright color, significantly improved product quality, and solved the problem of excessive acidification of fried food.

4. The oil-water separation surface is equipped with an observation glass tube and an oil drain valve detection device. The water level line can be more accurate.

5. Equipped with upper and lower double-layer mesh belts to avoid product floating and make food frying more uniform.

6. Advanced and high-efficiency heating system, the oil tank adopts heat preservation technology, which not only saves energy but also improves work efficiency. Reduced unit cost. The oil-water interface part adopts the ventilation pipe to dissipate heat, which greatly prolongs the service life of the oil. The upper part of the oil is heated and the lower part is cooled to prevent the water temperature from being too high and boiling. The oil and water are discharged separately, which makes it easier to clean the residue and change the oil.

7. With this frying equipment, the food residues produced during the frying process can sink into the lower funnel through the filtration of water and be discharged through the sewage outlet, which not only achieves the function of filtering oil, but also does not waste oil.

Technical Data

| Model | GG-LZG5000A |

| Heating Type | Gas |

| Power(KW) | convey1.5 |

| Size(MM) | 5200*1700*2300 |

| Weight(KG) | 1600 |

| Capacity(KG) | 500 |

| Mesh Belt Width(MM) | 800 |

| Oil discharge(L) | 1850 |

| Air consumption | 34cube |

| Burner | 30WKcal |

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP