Features

Introduction of Automatic Stick Biscuit Machine

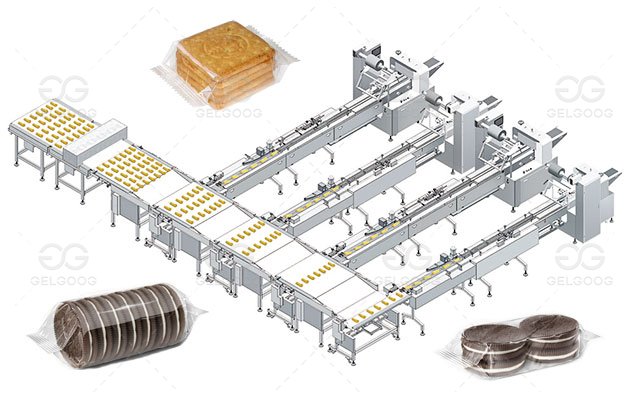

This production line is a special equipment for making stick biscuits, the types of biscuits produced are diverse and the output is large. It is the first choice for many biscuit factories. It is controlled by PLC and has a high degree of automation, which is widely loved by manufacturers.

Scope of Application of Stick Biscuit Production Line:

This production line is a special equipment for making stick biscuits, the types of biscuits produced are diverse and the output is large. It is the first choice for many biscuit factories. It is controlled by PLC and has a high degree of automation, which is widely loved by manufacturers.

Scope of Application of Stick Biscuit Production Line:

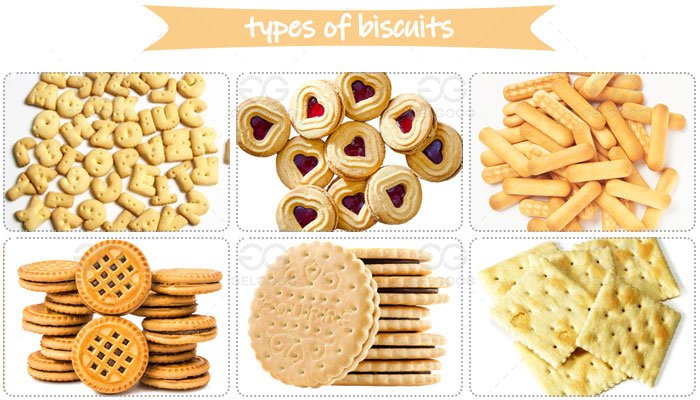

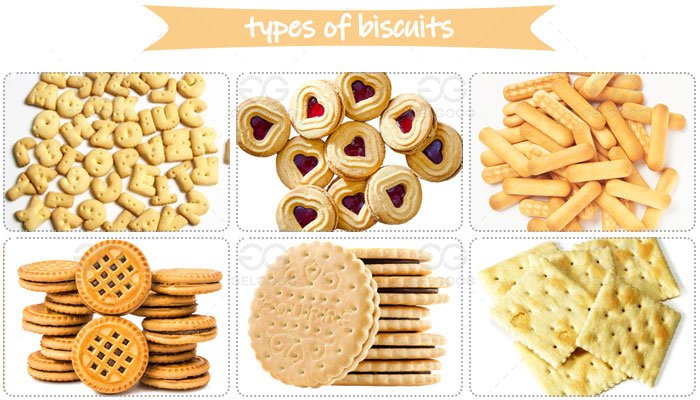

This line is suitable for the production of all kinds of hard and soft biscuits, such as sandwich biscuits, two-color biscuits, soda biscuits, crackers, seaweed biscuits, cookies, milk stick biscuits, vegetables biscuit, and other biscuits.

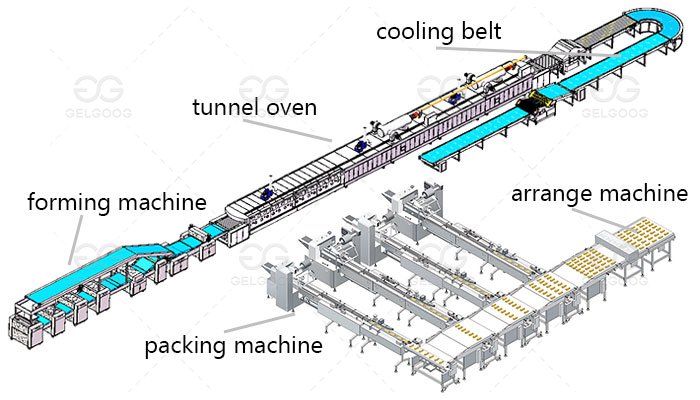

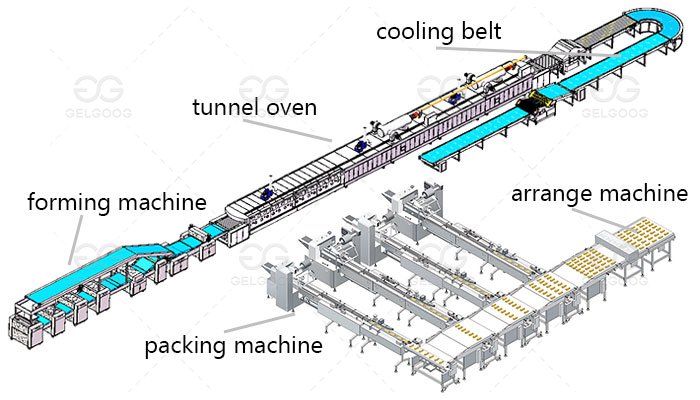

The Technological Process of Stick Biscuit Machine

Pretreatment of raw materials --- dough preparation --- pressing dough --- forming into biscuit --- baking --- oil spraying --- cooling --- sterilization --- packaging.

Main Equipment of Stick Biscuit Making Machine:

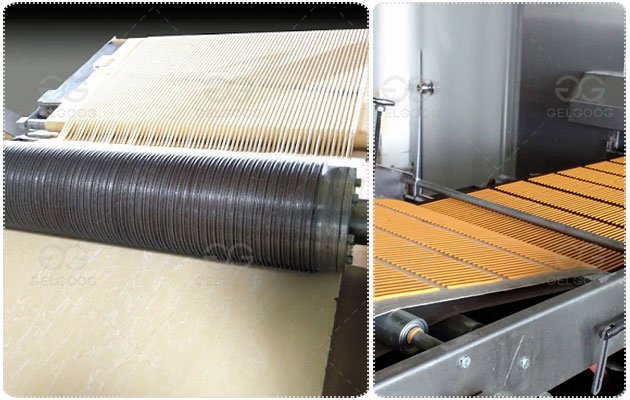

1. Pressing: The prepared dough should be rolled into a dough sheet with uniform thickness, flat shape, smooth surface and fine texture.

① Rolling of hard biscuit dough: The dough should be allowed to stand for a period of time before rolling. The purpose is to eliminate the internal tension formed by the stretching of the dough during mixing, reduce the viscosity and elasticity of the dough, and improve the process performance of gluten and the quality of products.

The length of the standing time depends on the temperature of the dough. Generally, the dough temperature is high and the standing time is short; the temperature is low and the standing time is long. If the dough temperature reaches 40°C, let it stand for 10-20 minutes.

②Rolling of soft biscuit dough: The crisp dough contains more oil and sugar, and the rolled dough pieces are soft and easy to break, so they should not be rolled many times. The crisp dough does not need to stand for a long time before rolling.

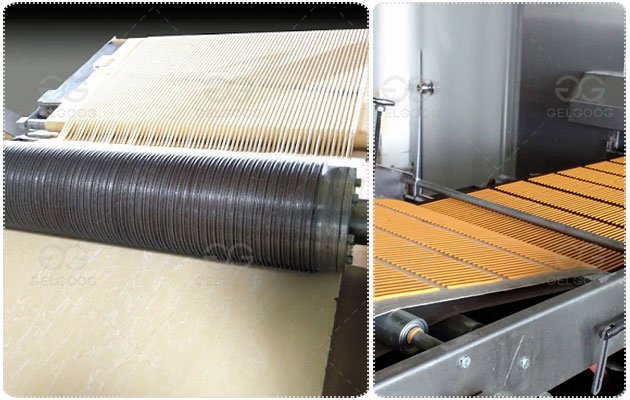

2. Forming: The dough slice rolled by the rolling process are formed into biscuit of various shapes by a forming machine.

2. Forming: The dough slice rolled by the rolling process are formed into biscuit of various shapes by a forming machine.

3. Baking: Generally, the baking temperature is kept at about 230-270℃, and should not exceed 290℃. If the temperature of the baking oven is higher, the baking time can be appropriately shortened. If the furnace temperature is too high or too low, it will affect the quality of the finished product.

4. Cooling: The temperature difference between the surface layer and the center of the baked biscuits is large, the outer temperature is high, the inner temperature is low, and the temperature emission is slow. In order to prevent the biscuits from shrinking and cracking, they must be cooled before packaging.

5. Packaging: Although biscuits are a kind of storage-resistant food, storage conditions must also be considered. Suitable storage conditions for biscuits are places with low temperature, dryness, good air circulation, clean air and avoiding sunlight. The storage temperature should be around 20℃, and the relative humidity should not exceed 70-75%.

The factory also has various types of automatic stick biscuit machine, and we will recommend suitable equipment according to different scales. The quality is guaranteed and the price is affordable.

Technical Data

| Name | Technical Parameter | |

| 1 | Dough Mixer Machine |

Motor power: 5.5kw

Tipping bucket power: 0.75kw

Voltage: 380v/50hz

Size: 1250*740*1300mm

Mixing time: 10-15min

Material: stainless steel hopper, frame A3 carbon steel

|

| 2 | Tough Biscuit Molder |

Power: 5.5kw

Dimensions: 4800*1050*1700mm

Production capacity: 150-200kgh

Voltage: 380v/50hz

Weight: 2800kg

Material: shell stainless steel, frame A3 carbon steel

|

| 3 | Crisp Biscuit Molder |

Power: 2.2kw

Dimensions: 1800*1000*1250mm

Production capacity: 150-200kgh

Roller diameter: 248

Weight: 500kg

|

| 4 | Tunnel Oven |

Heating method: Electricity

Power: 100-120kw

Size 20000*1000*1300mm

Number of knots: 5 knots (normally 4 meters equals 1 knot)

Baking capacity: 150-200kg/h

Weight: 8000kg

|

| 5 | Biscuit Sprayer |

Power: 2.2kw

Dimensions: 1800*1000*1850mm

Weight: 500kg

Material: shell stainless steel, frame A3 carbon steel

|

| 6 | Cooling Conveyor Belt |

Power: 1.1kw

Size: 10000*700*800mm

Weight: 600kg

Material: stainless steel

Conveying method: mesh belt

|

| 7 | Biscuit Sorting Machine |

Power: 2.2kw

Voltage: 380v/50hz

Dimensions: 2600*1000*1200

Weight: 700kg

|

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP