Features

The industrial cookie production line can produce cookies that are loved by many consumers. We produce it according to customer needs and can provide production lines of various specifications.

We have the ability to provide a variety of cookie processing solutions from small, medium to large volumes. At present, the production line have been sold to more than 30 countries in the world.

Cookies Manufacturing Process

The cookie making process starts with the dough being squeezed through the mold head of a cookie machine, forming various shapes. These are placed on baking trays and baked in a rotary or tunnel oven until perfectly golden. Once baked, the cookies are conveyed for cooling.

After cooling, the cookies are sterilized and carefully packaged, ensuring they are safe and ready for distribution. This meticulous process guarantees the quality and consistency of each batch of cookies.

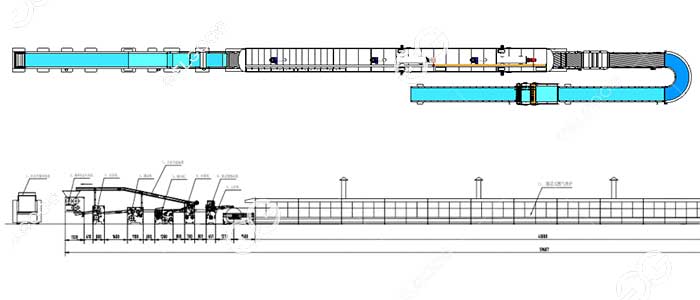

Automatic Cookie Production Line Composition

The production line comprises several essential machines. Flour mixers blend raw materials into a consistent batter, while cookie forming machines shape the batter into desired forms. The cookies are then baked in hot air rotary ovens or steel belt tunnel ovens, ensuring even baking and a perfect texture.

After baking, the cookies pass through cooling lines to solidify and stabilize. The line also includes a biscuit crusher machine for creating crumbs if needed, and a biscuit arranging machine to neatly organize the cookies. Finally, the packaging machine wraps the cookies in protective packaging, completing the process.

Video of Making Cookies

Features of Industrial Cookie Production Line

- The cookie machine can produce a large amount of cookies, the thickness of the cookies can be adjusted arbitrarily, and the molds can be changed arbitrarily according to the pattern of the market.

- We understand your stringent demands for safety and hygiene, which is why our cookie plants are meticulously designed and manufactured in strict accordance with GMP standards.

- As an automatic cookie production line manufacturer, we provides customers with hundreds of molds and dozens of process formulas. By changing the molds and process formulas, different cookies can be produced.

- This line has novel design, compact structure and high degree of automation. From stirring to forming, waste recycling, baking, cooling, and packaging, it is fully automatic and completed at one time.

As an experienced industrial cookie production line manufacturer, we provide standard configurations, and we can also provide different solutions according to the different needs of each project. Email: lisa@gelgoog.com, Whatsapp/Wechat/Phone: +8615515571373.

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP