Features

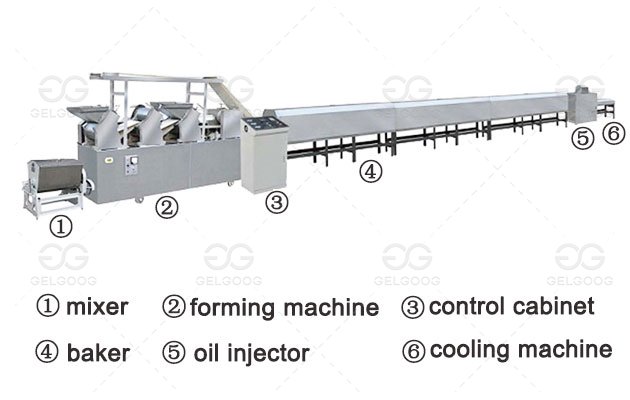

This ladyfinger making machine absorbs the technology of similar products at home and abroad, combines its own characteristics to manufacture, and automatically produces ladyfinger biscuits from feeding to forming, baking, conveying and cooling, and waste recycling. There are various models to meet different biscuit factories.

We can design a suitable solution according to the customer's plant requirements, capacity, degree of automation, and economic cost estimation. This production line is suitable for the production of crisp biscuits, tough biscuits, fermented biscuits, cookies, sandwich biscuits, egg round biscuits, and decorative biscuits.

We can design a suitable solution according to the customer's plant requirements, capacity, degree of automation, and economic cost estimation. This production line is suitable for the production of crisp biscuits, tough biscuits, fermented biscuits, cookies, sandwich biscuits, egg round biscuits, and decorative biscuits.

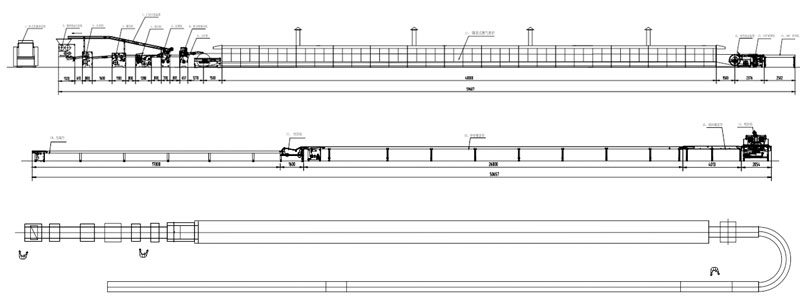

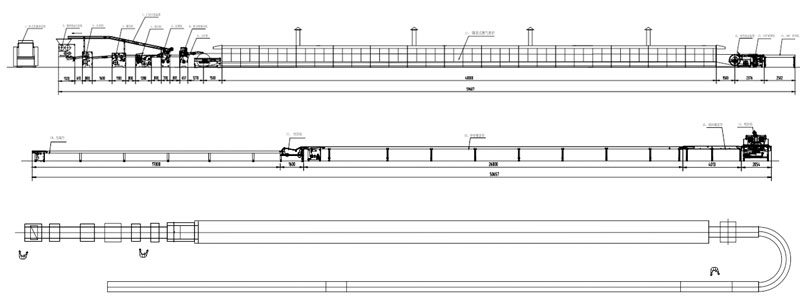

Technological Process of Ladyfinger Making Machine

Pretreatment of raw materials --- dough preparation --- rolling dough into sheet --- forming --- baking --- spraying --- cooling --- packaging.

The biscuit equipment is novel in design, compact in structure, and highly automated. There are dozens of process recipes, and various biscuits on the market, such as thin biscuits, soda biscuits, animal biscuits, vegetable biscuits, etc., can be produced by changing the mold and process formula.

Working Video of Lady Finger Biscuit Making Machine

The biscuit equipment is novel in design, compact in structure, and highly automated. There are dozens of process recipes, and various biscuits on the market, such as thin biscuits, soda biscuits, animal biscuits, vegetable biscuits, etc., can be produced by changing the mold and process formula.

Working Video of Lady Finger Biscuit Making Machine

Features and Advantages of Automatic Ladyfinger Making Machine

1. It has the functions of automatic constant temperature, automatic baking, conveying, automatic fuel injection, and cooling.

2. Wide range of uses, suitable for making all kinds of biscuits, such as crisp biscuits, tough biscuits and so on.

3. The baked food has good color, fragrance and shape, with multiple functions and easy to change varieties.

4. It has the advantages of high output, energy saving, reasonable structure, simple operation and high degree of automation.

Technical Data

| GG-400 Biscuit Making Machine | ||

| Name | Technical Parameter | |

| 1 | Dough Mixer Machine |

Motor power: 5.5kw

Tipping bucket power: 0.75kw

Voltage: 380v/50hz

Size: 1250*740*1300mm

Mixing time: 10-15min

Material: stainless steel hopper, frame A3 carbon steel

|

| 2 | Tough Biscuit Molder |

Power: 5.5kw

Dimensions: 4800*1050*1700mm

Production capacity: 150-200kgh

Voltage: 380v/50hz

Weight: 2800kg

Material: shell stainless steel, frame A3 carbon steel

|

| 3 | Crisp Biscuit Molder |

Power: 2.2kw

Dimensions: 1800*1000*1250mm

Production capacity: 150-200kgh

Roller diameter: 248

Weight: 500kg

|

| 4 | Tunnel Oven |

Heating method: Electricity

Power: 100-120kw

Size 20000*1000*1300mm

Number of knots: 5 knots (normally 4 meters equals 1 knot)

Baking capacity: 150-200kg/h

Weight: 8000kg

|

| 5 | Biscuit Sprayer |

Power: 2.2kw

Dimensions: 1800*1000*1850mm

Weight: 500kg

Material: shell stainless steel, frame A3 carbon steel

|

| 6 | Cooling Conveyor Belt |

Power: 1.1kw

Size: 10000*700*800mm

Weight: 600kg

Material: stainless steel

Conveying method: mesh belt

|

| 7 | Biscuit Sorting Machine |

Power: 2.2kw

Voltage: 380v/50hz

Dimensions: 2600*1000*1200

Weight: 700kg

|

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP