Features

Description:

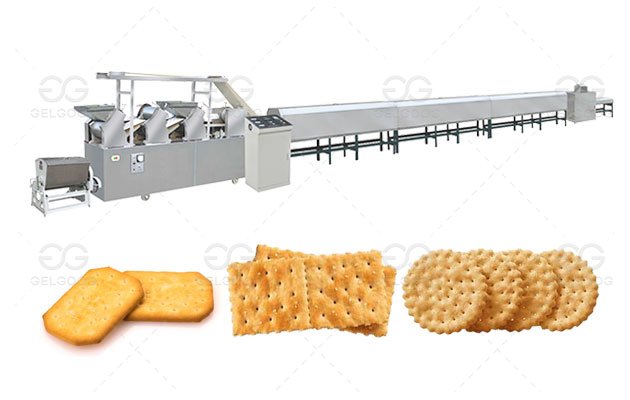

Salted crackers making machine is usually used to make crispy salt crackers. With many models and variety output, which are suitable for developing biscuit businesses of different scales.

Widely Used:

Salted crackers making machine is usually used to make crispy salt crackers. With many models and variety output, which are suitable for developing biscuit businesses of different scales.

Widely Used:

The biscuit machine can produce biscuits with different flavors and shapes, including crisp biscuits, tough biscuits, soda biscuits, cookies, sandwich biscuits, etc., and can also customize machines according to customer needs.

Features and Advantages:

1. The saltine crackers making machine is controlled by PLC, with high production continuity and high work efficiency.

2. This machine has the characteristics of high degree of automation, stable quality, energy saving, clean and hygienic, and simple operation.

3. The equipment is made of high-quality materials, and some of the food contact parts are made of 304 stainless steel to ensure food safety and sanitation.

4. The output and energy options (electric heating or gas type) of salted crackers making machine can be configured according to customer needs.

5. It can produce biscuits of various shapes, including crisp biscuits, tough biscuits, soda biscuits, cookies, sandwich biscuits and so on.

6. We have professional engineers to train their staff, responsible for the commissioning and installation of the machine, and will also provide the best technical formula support.

Manufacturing Processes:

Prepare the raw materials --- ingredients --- mixing --- forming --- conveying in front of the oven --- entering the oven --- zone 1 finalizing --- zone 2 baking --- zone 3 coloring --- oil injection (oil temperature 60 °-80°) --- cooling --- automatically sorting --- packaging. Please watch the working video below.

Components of Automatic Salted Crackers Making Machine:

1. Mixing machine: The mixer and blades of this equipment have been improved to make more uniform mixing. The dough made is of moderate consistency and easy to handle.

2. Dough cutting machine: It mainly divides the whole piece of dough into several smaller pieces of dough through the up and down movement of the cutter.

3. Biscuit forming machine: This machine is used for biscuit roll printing and demoulding. The dough is squeezed by the roller to form biscuits of various shapes.

4. Tunnel oven: used to bake and shape the formed biscuits. Two types of electric heating type and gas type can be selected. Baking range: bread, cakes, moon cakes, biscuits and other similar baked goods.

5. Oil sprayer: mainly spray cooking oil on the surface of the biscuits after the oven to improve the taste and quality of the biscuits.

6. Turning machine: It is mainly suitable for insufficient workshops, it can be used for turning to save factory space, and it can also be used for cooling biscuits.

7. Cake sorting machine: Arrange the biscuits after cooling and turning to lay a good foundation for the next packaging and improve packaging efficiency.

8. Cooling conveyor line: mainly used for natural cooling of biscuits and transition for the next operation.

9. Packaging machine: This is the final step of the biscuit line. The cooled biscuit is packaged, which can be applied to different styles of packaging (customized according to customer needs).

If you want to start biscuit business, please choose our biscuit machine, there are different models can be choose, and the price is very affordable.

If you want to start biscuit business, please choose our biscuit machine, there are different models can be choose, and the price is very affordable.

Technical Data

| Name | Technical Parameter | |

| 1 | Dough Mixer Machine |

Motor power: 5.5kw

Tipping bucket power: 0.75kw

Voltage: 380v/50hz

Size: 1250*740*1300mm

Mixing time: 10-15min

Material: stainless steel hopper, frame A3 carbon steel

|

| 2 | Tough Biscuit Molder |

Power: 5.5kw

Dimensions: 4800*1050*1700mm

Production capacity: 150-200kgh

Voltage: 380v/50hz

Weight: 2800kg

Material: shell stainless steel, frame A3 carbon steel

|

| 3 | Crisp Biscuit Molder |

Power: 2.2kw

Dimensions: 1800*1000*1250mm

Production capacity: 150-200kgh

Roller diameter: 248

Weight: 500kg

|

| 4 | Tunnel Oven |

Heating method: Electricity

Power: 100-120kw

Size 20000*1000*1300mm

Number of knots: 5 knots (normally 4 meters equals 1 knot)

Baking capacity: 150-200kg/h

Weight: 8000kg

|

| 5 | Biscuit Sprayer |

Power: 2.2kw

Dimensions: 1800*1000*1850mm

Weight: 500kg

Material: shell stainless steel, frame A3 carbon steel

|

| 6 | Cooling Conveyor Belt |

Power: 1.1kw

Size: 10000*700*800mm

Weight: 600kg

Material: stainless steel

Conveying method: mesh belt

|

| 7 | Biscuit Sorting Machine |

Power: 2.2kw

Voltage: 380v/50hz

Dimensions: 2600*1000*1200

Weight: 700kg

|

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP