Features

As one of the professional wafer biscuit production line manufacturers in China, our factory has different types of wafer lines. This one has 27 plates and can bake wafers continuously.

In our factory, this machine is specially used to produce high-quality wafer biscuits, chocolate wafers., wafer sticks. The production line not only has large output, but also automated operation.

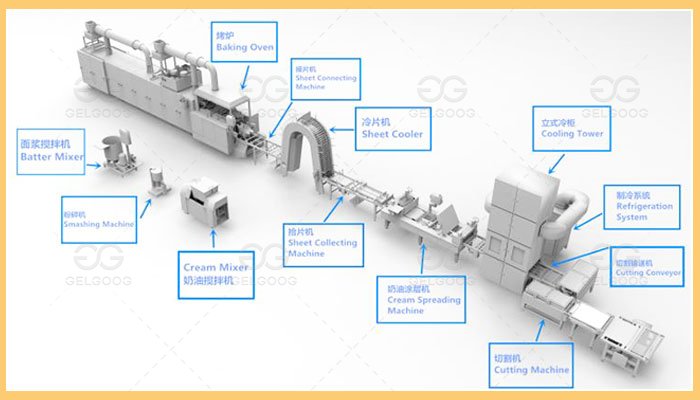

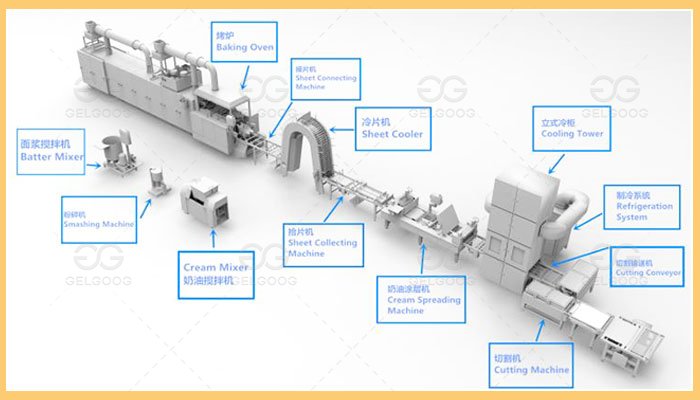

This plant mainly includes a batter mixer, a wafer baking oven, a picking machine, a cooler, a cream spreading machine, a chocolate coating machine, a vertical cooler, a wafer biscuit cutting machine, a wafer biscuit packaging machine, and a biscuit grinder machine.

Automatic Wafer Production Line Flow ChartIn our factory, this machine is specially used to produce high-quality wafer biscuits, chocolate wafers., wafer sticks. The production line not only has large output, but also automated operation.

This plant mainly includes a batter mixer, a wafer baking oven, a picking machine, a cooler, a cream spreading machine, a chocolate coating machine, a vertical cooler, a wafer biscuit cutting machine, a wafer biscuit packaging machine, and a biscuit grinder machine.

Batter mixing → baking wafer sheet → wafer biscuit delivery → wafer biscuit cooling → sprading cream → chocolate coating → cooling → wafer biscuit packaging.

Working Video of Chocolate Wafer Production Line

The industrial wafer biscuit production line can be equipped with the following equipment:

Chocolate wafer machine is a new generation product developed in China based on the structure of similar products at home and abroad, using electric heating or gas heating as the heat source. It successfully solves the problems of high production cost and large chromatic aberration on the surface of biscuits in production.

Features of Wafer Biscuit Production Line

1. According to the user's special or conventional needs, our automatic wafer line has different models to choose from, and can be customized.

2. This wafer production line adopts infrared measurement automatic temperature control system, PLC + touch screen automatic control.

3. The labor intensity of workers is low, the degree of automation is high, the maintenance is convenient, and wafer biscuit machine can be produced continuously for 24 hours.

4. The chocolate wafer biscuit making machine has high efficiency, and the average output per hour can reach at least 100 kg, which is energy-saving and electricity-saving.

5. The oven adopts a double oven chamber structure. The heating effect of the inner furnace chamber is better, and the service life of the mechanical part of the outer furnace chamber is longer.

Working Video of Chocolate Wafer Production Line

The industrial wafer biscuit production line can be equipped with the following equipment:

1. Wafer sheets picking machine: remove the wafer biscuits with chipped corners after baking to improve the yield.

2. Vertical freezer: Cool the wafers after applying cream in a space of ≤10℃ for a certain period of time to reduce the moisture content of the finished product, extend the shelf life, and make the taste more crispy.

3. Automatic packaging conveyor line: automatically arrange and transport the cut wafer biscuits to the packaging equipment for automatic packaging.

4. Sorting machine and chocolate coating line: arrange and disperse the wafer biscuits, automatically transport them to the chocolate coating equipment, coat the outer layer of chocolate, and package after cooling through the cooling tunnel.

Chocolate wafer machine is a new generation product developed in China based on the structure of similar products at home and abroad, using electric heating or gas heating as the heat source. It successfully solves the problems of high production cost and large chromatic aberration on the surface of biscuits in production.

Technical Data

| name | quantity | |

| 1 | Flat automatic gas heating oven | 1 |

| 2 | Splicing machine | 1 |

| 3 | Wafer sheet cooling machine | 1 |

| 4 | Cream spreading machine | 1 |

| 5 | Wafer cutting machine | 1 |

| 6 | Blender Machine | 1 |

| 7 | Cream mixer | 1 |

| 8 | Swashing Machine | 1 |

| 9 | Air compressor | 1 |

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP