Features

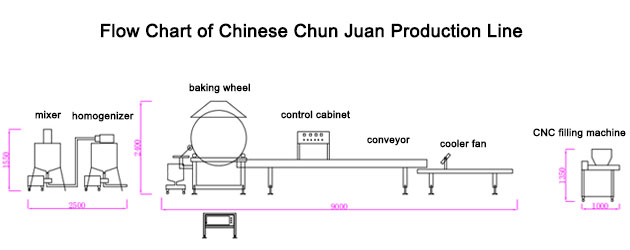

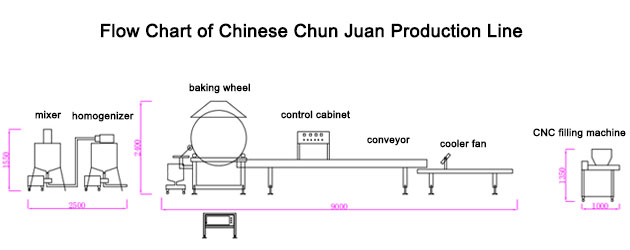

Chun Juan Machine is also called harumaki making machine, it is usually to make the chinese snack--chunjuan. The whole equipment is mainly composed of the baking part, filling part, conveying part, and wrapping part, which can be operated automatically.

The Features of Automatic Harumaki Making Machine

The Features of Automatic Harumaki Making Machine

1. The frame of the complete equipment is made of SUS304 stainless steel, which is clean and hygienic.

2. The mixer and slurry tank are made of 2.0 mm thick stainless steel plates, which are strong and durable.

3. The mold of the equipment is made of 6061 high-strength aluminum alloy, which has good corrosion resistance.

4. The whole chun juan machine is composed of dough mixer, homogenizer, baking wheel, CNC filling machine, electric control cabinet, conveyor belt, cooling fan, cooling conveyor belt, etc.

5. All panels of the whole equipment have a decorative thickness of 1.2mm and a reinforcement of 5mm-8mm.

Testing Video of Automatic Chun Juan Machine

4. The whole chun juan machine is composed of dough mixer, homogenizer, baking wheel, CNC filling machine, electric control cabinet, conveyor belt, cooling fan, cooling conveyor belt, etc.

5. All panels of the whole equipment have a decorative thickness of 1.2mm and a reinforcement of 5mm-8mm.

Testing Video of Automatic Chun Juan Machine

Manufacturing Processes of Harumaki Making Machine:

Pour the batter into the batter bucket, heat the baking wheel to 120°C, and then the batter adheres to the surface of the baking wheel. When the baking wheel rotates to 270-300 degrees, the batter is cooked. The shovel knife separates the spring roll wrappers on the conveyor belt, when it pass through the discharging port of the filling machine, the filling will evenly fall on each spring roll wrapper. After the combined part, the filling is wrapped with the spring roll wrapper, and finally the chun juan is formed.

GELGOOG developed the spring roll machine on which the wrapping procedures was automated, after that, GELGOOG have been creating a variety of automatic pastry machines such as Gyoza machine, Shaomai machine, Paozu machine, Crepe machine, etc. Our company has completed the integrated-production line including design, development, production, and sales-after service so that we can quickly respond to customer requirement and can obtain customer satisfaction.

Technical Data

| GG-CJX5000 Spring Roll Production Line | |||

| Name | Dimensiton(mm) | Power(KW) | No. |

| Spring Roll Wapper Part | 2200*2000*2200 | 59 | 1 |

| Stuffing Part | 700*600*1000 | 0.4 | 1 |

| Spring Roll Folding Part | 1700*500*1360 | 0.4 | 1 |

| Spring Roll Forming Part | 4030*500*1100 | 0.4 | 1 |

| Batter Mixer | 1300*600*900 | 1.1 | 1 |

| Batter Tank | 800*300*320 | / | 1 |

| Batter Pump | - | 0.55 | 2 |

| Capacity 3000-4000pcs/h | |||

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP