Features

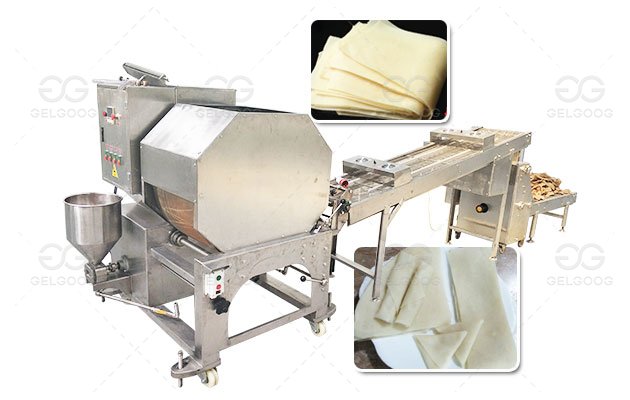

The samosa patti making machine can produce samosa patti with a thickness of 0.3-0.8 mm, it is a safe and reliable equipment for large output of samosa patti. One hour can produce 500-9000 pieces.

It has a high degree of automation and can realize automatic samosa patti baking, automatic cutting, automatic counting and other functions. Because of its affordable price and high quality, the machines are exported to Pakistan, Sri Lanka, Canada, the United States, etc.

Wide Range of Uses of Samosa Patti Making Machine in Pakistan

This machine is multifunctional, it can not only make samosa patti, but also spring roll wrappers, lumpia wrappers, egg roll wrappers, french pancakes, peking duck wrappers, crepes, etc., as well as other flake foods. This machine is suitable for frozen food factories, restaurants, fast food restaurants, etc.

How to Make Samosa Patti Step by Step

Pour the evenly stirred batter into the batter bucket, start to heat the baking wheel, when the temperature reaches 180℃, start the batter pump to send the batter to the nozzle. Operate the clutch lever to make the batter stick to the surface of baking wheel. When the baking wheel rotates to 270-300 degrees, the samosa patti batter is ripened and separated from the baking wheel automatically to form a samosa patti with a uniform thickness.

- Raw material preparation: Prepare the raw materials such as flour, water, oil and salt according to the proportion and put them into the raw material storage bin.

- Batter mixing: The mixing system of the dough mixer mixes the raw materials into a uniform batter. Pour the batter into the storage tank.

- Baking: The baking wheel of the samosa patti machine in Pakistan bakes the batter into wraps by rotating 360°.

- Cooling: After baking, the samosa patti are conveyed to the cooling area for natural cooling.

- Separation and cutting: The cooled samosa wrappers are conveyed to the separation and cutting area, where the machine automatically separates the samosa patti and cuts them into the required shape and size of the samosa patti.

Working Video of Samosa Patti Making Machine in Pakistan

Advantages of Samosa Patti Sheet Making Machine

- The square and other shapes of samosa patti with different sizes and yields can be customized according to your needs.

- Adopt advanced temperature control system to achieve zero temperature error, no heat waste, achieve the purpose of energy saving and environmental protection, and reduce energy costs.

- The operating system of samosa patti maker machine is simple and fully automated production. The entire production process is highly efficient.

- It can be operated by one person, saving labor costs to the greatest extent. After pressing the switch, the machine will automatically sizing to produce samosa patti.

- The size of the Pakistan samosa patti product is uniform, the surface is smooth, and it is far more beautiful than handmade.

- The whole automatic samosa sheet machine is made of high-quality stainless steel, the structural parts do not need to be refueled, no rust, durable, and the normal service life is 6-8 years.

- Automatic noise processing technology, the operating noise of the whole machine is controlled below 50 decibels to ensure that the operator has a good working environment.

- The samosa patti making machine price in Pakistan is related to the automation level and output of the equipment. You can contact us for more information and quotation.

Our company is a food processing machinery enterprise integrating equipment R&D, manufacturing and sales. We have a strong technical research and development team, and with the concept of tailor-made for customers, we provide customers at home and abroad with affordable price machine for samosa patti and other product.

There are different models for you to choose, if you want to know the samosa patti machine price in Pakistan, Welcome to come for consultation, we will provide you with a satisfactory solution.

Technical Data

| Model | GGSR400-6X | GGSR400-8X |

| Roasting wheel diameter | 600MM | 800MM |

| Skinning width | 400MM | 420MM |

| Skinning speed | 230M/H | 389M/H |

| Input power | 24KW | 30KW |

| Heating type | Electric | Electric |

Size Size |

5000*1300*1500MM | 5500*1300*1500MM |

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP