Features

The Vietnamese rice paper spring roll machine is suitale for making high quality and same size of Vietnamese spring rolls. It has been developed to streamline the process of making Vietnamese spring rolls, Goi cuon.

By employing this professional production line, the production of these Vietnamese rice paper spring rolls is not only expedited but also stays true to their authentic taste and texture.

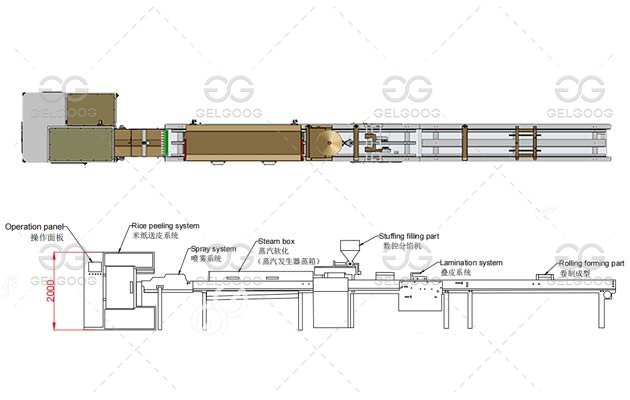

Working Principle of Vietnamese Spring Roll Machine

- Feeding: The user places the rice paper and desired fillings in the designated area of the machine.

- Filling part: The filling part of the machine drops the fillings in equal portions onto the rice paper according to the positioning points.

- Folding and rolling part: Fold the two ends of the rice paper by air blowing, then wrap the filling in it, and roll it into shape through the rolling device.

- Output: The completed Vietnamese rice paper spring rolls are conveyed to the next process such as packaging and quick freezing. Ready for sale.

Diverse Models: Versatility for Every Requirement

Our Vietnamese rice paper spring roll machines are available in a variety of models, tailored to meet the diverse production needs from medium to large-scale commercial kitchens. Each model is meticulously crafted and engineered for optimal efficiency, ensuring that you can effortlessly produce high-quality Vietnamese spring rolls.

- Model 1: Semi-Automatic

Balances automation with manual control for customization.

Suitable for medium-volume production.

User-friendly interface for easy operation.

- Model 2: Fully Automatic High-Capacity

Designed for high-volume commercial production.

Fully automated system for consistent output.

Robust construction for long-term use.

Advantages of Vietnamese Spring Roll Machine

- Precision Engineering: Our machines are well-made to ensure that every Vietnamese spring roll is of high quality. The machines are produced to the highest standards, delivering consistent sizes and different flavours.

- Easy to Operate: The machines are equipped with an intuitive control system that simplifies the operation process. This design making it easy for both beginners and seasoned professionals to create delicious spring rolls with minimal effort.

- Consistent Quality: The rice paper spring roll machines guarantee consistent quality in every roll, eliminating the variability that comes with handcrafting.

- Time and Labor Saving: Automating the process of making spring rolls significantly reduces the time and labor required, allowing businesses to focus on other aspects of their operations.

- Customizable Settings: Adjustable settings allow you to customize the thickness of the rice paper, the size of the rolls, and the filling capacity to suit different recipes and preferences.

Video of Vietnamese Rice Paper Spring Roll Machine

Technical Data

| GG-CJX5000 | |||

| Name | Dimensiton(mm) | Power(KW) | No. |

| Spring Roll Wapper Part | 2200*2000*2200 | 59 | 1 |

| Stuffing Part | 700*600*1000 | 0.4 | 1 |

| Spring Roll Folding Part | 1700*500*1360 | 0.4 | 1 |

| Spring Roll Forming Part | 4030*500*1100 | 0.4 | 1 |

| Batter Mixer | 1300*600*900 | 1.1 | 1 |

| Batter Tank | 800*300*320 | / | 1 |

| Batter Pump | - | 0.55 | 2 |

| Capacity 3000-4000pcs/h | |||

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP