Features

The chiffon cake processing machine can make healthy and delicious chiffon cakes. Our factory can meet the different needs of customers to produce other cakes, such as swiss rolls cakes, cupcakes, sponge cakes and so on.

At present, you can see all kinds of cakes in all kinds of cake shops, all of them are exquisite and delicious, and all the happiness is at the moment of entering the cake. The exhaustion of work slowly dissipated, leaving only the relaxed pleasure full of satisfaction. Today, we understand the process and equipment of the chiffon cake production line.

At present, you can see all kinds of cakes in all kinds of cake shops, all of them are exquisite and delicious, and all the happiness is at the moment of entering the cake. The exhaustion of work slowly dissipated, leaving only the relaxed pleasure full of satisfaction. Today, we understand the process and equipment of the chiffon cake production line.

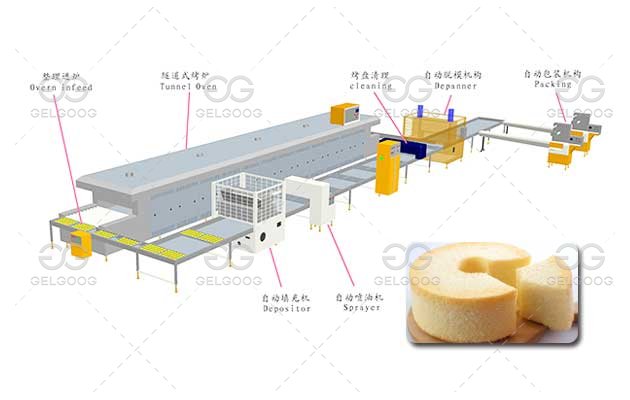

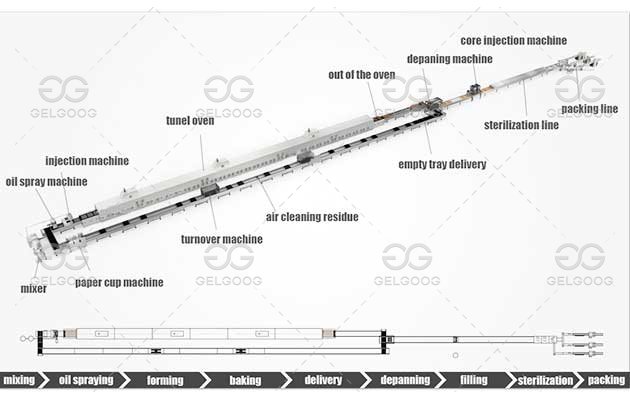

Chiffon Cake Machine Process Flow

Sift flour, beat eggs → stir → lift the slurry → fill into the mold → enter the oven → bake → out of the oven → cakes demould → finishing the baking pan → (spray oil → fill the batter into the mold, repeat the above steps) → sterilization → cooling → chiffon cakes packaging.

Equipment for Cake Processing Machine

- Sifting machine: The flour (cake flour) used in cake production is hydrophilic and easy to agglomerate, which affects the stirring effect. Therefore, before pouring into the whisk, the cake flour is easy to stir and shape after passing through the screen.

- Mixing machine: It refers to the stirring of butter, cream, eggs (to increase the flavor and color of the cake), etc., to evenly distribute the air in the tissue to form a dense pore shape. Small-scale production is generally stirred by spherical agitators, and large-scale production is produced by aerated stirring.

- Filling machine: The roller type filling machine has a simple structure, is suitable for various cakes and shapes, and has a large weight adjustment range. It is a mainstream product in the mass production of cakes.

- Oil spraying machine: Spray the mold release oil (olive oil, butter, salad oil, etc.) evenly on the inner wall of the baking pan cake cup, so that the baked cake can be released quickly and overcome the phenomenon of cake sticking.

- Cake tunnel oven: Through the PLC intelligent control system, the intelligent control of the distribution mode is implemented. The cake produces relative motion between the conveying chain plate, steel belt or mesh belt and the heating element or direct-fired burning rod to complete continuous and uniform baking and conveying. The tunnel furnace is set up to control the upper and lower temperature zones separately to meet the heating requirements of the cake on the surface and bottom. The tunnel furnace has the characteristics of continuous production, high efficiency, labor saving, etc., and the processing quality is stable. The length and width of the oven can be customized according to customer needs

- Depanning machine: The equipment that separates the chiffon cake from the baking tray saves labor, reduces pollution, and forms an automated form of operation.

- Cooling conveyor and sterilization line: Bake mature cakes, after cooling, into packaging equipment. In order to ensure that the cake is not contaminated with bacteria during the cooling process, the air near the cake is sterilized (ultraviolet germicidal lamp) during cooling

Video of Automatic Chiffon Cake Machine

Technical Data

|

Model

|

GG-Cake

|

|

Capacity

|

4807pcs/h(cake weight 78g/pc)

|

|

1718pcs/h(cake weight 32g/pc)

|

|

|

Size of baking plate

|

600*540mm

|

|

24pc cake/plate(cake weight 78g/pc)

|

|

|

48pc cake/plate(cake weight 32g)

|

|

|

Baking time

|

12 minutes

|

|

Baking temperature

|

185℃—210℃

|

|

Heating type

|

gas/electrical

|

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP