Features

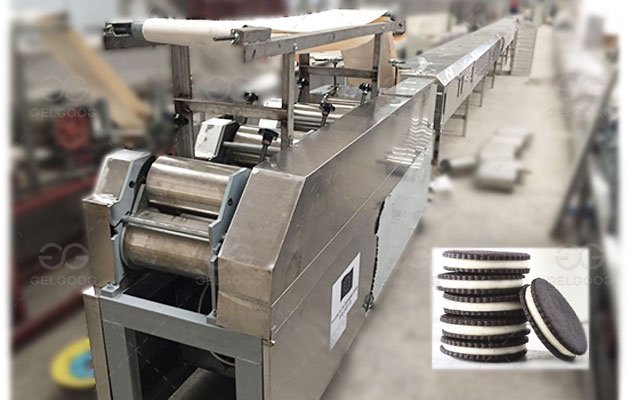

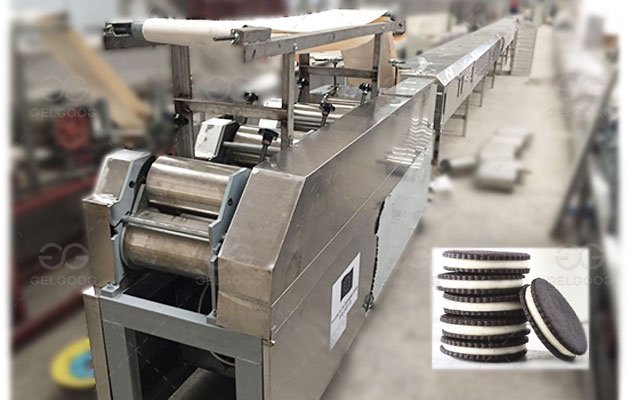

The automatic sandwich cookie machine has two heating methods: electric heating and gas heating, which is suitable for the production of various sandwich cookies. The equipment is novel in design, compact in structure, high quality, and strong and durable.

The entire production line is mainly composed of the following equipment: Mixing --- Forming --- Baking --- Spraying --- Cooling --- Finishing --- Packaging. The degree of automation is high, and no labor is required in the production process, save labor cost.

The Features of Sandwich Biscuit Machine

Working Video of Sandwich Cookie Making Machine

Advantages of Automatic Sandwich Cookie Machine:

The Features of Sandwich Biscuit Machine

① The rolling effect is good, and the thickness of the pressed dough strip is uniform.

② Easy to operate, the thickness of the sheet and the number of times of lamination can be adjusted arbitrarily.

③ High thermal efficiency, good energy-saving effect, reaching more than 30%, and good sanitary conditions and long service life.

④ The baking program is controlled by PLC, with four zones and eight sections for automatic temperature control, and an observation window. Adopt imported burner and gas control system.

Working Video of Sandwich Cookie Making Machine

Advantages of Automatic Sandwich Cookie Machine:

1. The oven has good heat preservation performance, the produced biscuits are full of color and fragrance, and have good long-term economic benefits and energy-saving characteristics.

2. This machine can produce various kinds of biscuits, and it can produce biscuits of various shapes by changing the mold.

3. The parts in contact with food are all made of 304 stainless steel, and the food produced is more healthy and hygienic.

4. The degree of automation is high, from feeding to calendering, forming, waste recycling, baking, oil injection, and cooling, all at one time.

5. This biscuit production line adopts imported electrical components, frequency conversion speed regulation, energy saving, single control and joint control.

5. This biscuit production line adopts imported electrical components, frequency conversion speed regulation, energy saving, single control and joint control.

Technical Data

| GG-400 Biscuit Making Machine | ||

| Name | Technical Parameter | |

| 1 | Dough Mixer Machine |

Motor power: 5.5kw

Tipping bucket power: 0.75kw

Voltage: 380v/50hz

Size: 1250*740*1300mm

Mixing time: 10-15min

Material: stainless steel hopper, frame A3 carbon steel

|

| 2 | Tough Biscuit Molder |

Power: 5.5kw

Dimensions: 4800*1050*1700mm

Production capacity: 150-200kgh

Voltage: 380v/50hz

Weight: 2800kg

Material: shell stainless steel, frame A3 carbon steel

|

| 3 | Crisp Biscuit Molder |

Power: 2.2kw

Dimensions: 1800*1000*1250mm

Production capacity: 150-200kgh

Roller diameter: 248

Weight: 500kg

|

| 4 | Tunnel Oven |

Heating method: Electricity

Power: 100-120kw

Size 20000*1000*1300mm

Number of knots: 5 knots (normally 4 meters equals 1 knot)

Baking capacity: 150-200kg/h

Weight: 8000kg

|

| 5 | Biscuit Sprayer |

Power: 2.2kw

Dimensions: 1800*1000*1850mm

Weight: 500kg

Material: shell stainless steel, frame A3 carbon steel

|

| 6 | Cooling Conveyor Belt |

Power: 1.1kw

Size: 10000*700*800mm

Weight: 600kg

Material: stainless steel

Conveying method: mesh belt

|

| 7 | Biscuit Sorting Machine |

Power: 2.2kw

Voltage: 380v/50hz

Dimensions: 2600*1000*1200

Weight: 700kg

|

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP