Features

The indomie noodles making machine is a professional equipment used to produce fried indomie noodles. The equipment has a high degree of automation, which can realize unmanned production and reduce labor costs.

This line is a new generation product developed and produced by our company on the basis of researching similar products at home and abroad and combining with the needs of the mass consumer market in my country.

This line is a new generation product developed and produced by our company on the basis of researching similar products at home and abroad and combining with the needs of the mass consumer market in my country.

Features of Automatic Indomie Noodles Making Machine

♢ Perfect processing technology, compact structure, novel design, stable and reliable performance.

♢ From flour to instant noodles can be completed at one time, with a high degree of automation and simple operation.

♢ This indomie noodle machine has the characteristics of diversified output, energy saving and quick results, especially suitable for small and medium-sized enterprises.

♢ The rehydration time of the equipment is short, and the finished product has good elasticity, smoothness and transparency.

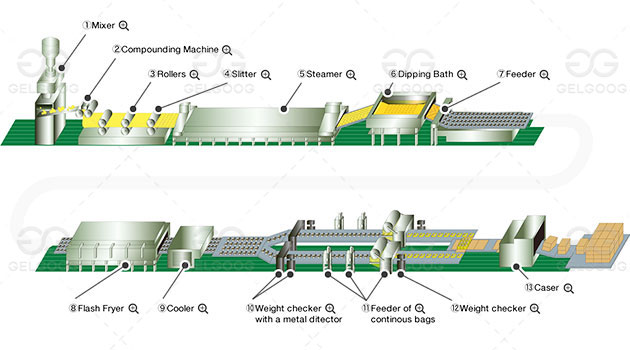

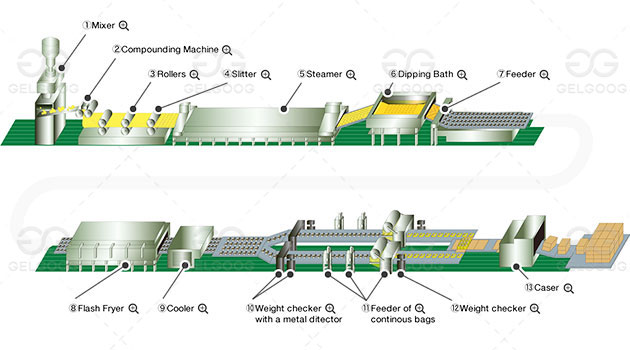

The composition of the fried indomie noodle machine: brine mixer---metering supply device---two-speed kneading machine---cooking machine---calendering machine---steaming noodle machine---cutting machine---continuous frying machine- --Air-cooled machine---Conveyor---Pillow packing machine

Working Video of Indomie Noodles Making Machine For Sale

Reference Recipe for Fired Indomie Noodles:

- Flour: 200kg (special flour for instant noodles: moisture below 13.8%, protein 10.5-11%)

- Table salt: 4.5kg

- Strengthening agent: 600g

- Emulsifier: 500g

- Pigment: 25g

- Tapioca starch: 20kg

Common Types of Indomie Noodles:

Services Support:

1. Assist you in the selection of indomie noodles making machine, process design, and plant optimization layout.

2. Compensation schemes for material changes can be designed for your products, and live demonstrations can be carried out.

3. Special design, manufacture and application test can be carried out according to your needs, and targeted training can be provided.

4. Design a reasonable packaging and transportation plan for you, send technicians to install and debug, and train personnel.

5. The fried indomie noodle machine is guaranteed for one year, long-term preferential, and spare parts are supplied.

Technical Data

| No | Equipments | Quantity | Remark |

| 1 | Brine metrology mixer | 2set |

1.5 kw Pump power 0.75 kw Capacity: 1000 l/unit |

| 2 | Supply metering device | 1set |

Volume: 110 L Pump Power: 0.75 kw |

| 3 | Double speed dough mixer | 2set |

Power :11/14kw Capacity:200 kg/pan |

| 4 | Disc curing machine | 1set |

Power :4 kw, Tray: 2000 *410 mm |

| 5 | Single continuous rolling machine | 1set |

Paste width: 650 Power: 29.5kw 10 pcs steel roller |

| 6 | Single-layer steamed noodles machine | 1set |

30 meters long Power: 3 kw power Fan: 0.37 kw * 2 water seal |

| 7 | Cutting and folding machine | 1set |

Main drive: 1.5 kw Air knife: 0.9 kw |

| 8 | Fried dryer | 1set |

Main drive: 3kw Lifting: 2.2 kw Circulating pump: 15 kw gear pump 2.2 kw air knife 0.9 kw *2 |

| 9 | Strong Air cooling device | 1 set | Blower: 0.37 kw*14,Fan: 3 kw |

| 10 | Shunt conveyor | 1 set | Main drive: 1.1 kw |

| 10 | Conveyor | 3set | Power: 0.37 kw*3 |

| 11 | Products conveyor | 3set | stainless steel panel |

| 12 | Electric control cabinet | 1 set |

Frequency control of motor speed PLC program control |

Related Posts

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail

Contact

Contact

Whatsapp

Whatsapp

TOP

TOP